ARW Product Characteristics

ARW Burkani Rockwool(s) are made to meet all major requirements in the market. Following explains common characteristics and specification of our products.

1.Thermal Insulation

Each country has its own thermal insulation code depending on the climate conditions, building designs, types of building materials, and percentage of the opening in the walls.

According to the Saudi Standard SASO 2856/2014, the maximum Thermal Transmittance (U Value) of the walls and roofs have been adopted as below tables. The above-mentioned standard is issued by SASO in cooperation with Saudi Energy Efficiency Center (SEEC) on April 2014.

According to the Saudi Standard SASO 2856/2014, the maximum Thermal Transmittance (U Value) of the walls and roofs have been adopted as below tables. The above-mentioned standard is issued by SASO in cooperation with Saudi Energy Efficiency Center (SEEC) on April 2014.

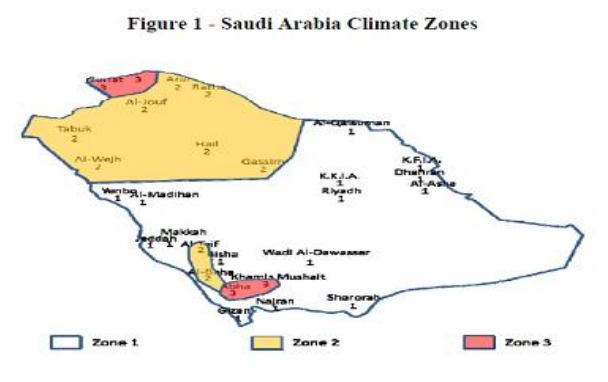

Saudi Arabia is divided into three main thermal zones according to the climate conditions.

Table 1 is applicable for Low-rise / Residential buildings (not built by/for governmental entities) and it should be implemented from the date of 25/11/2014 until January 1, 2017, beyond this date table, 2 will be applicable for this type of buildings.

| Table:1 – The thermal transmittance (U-Values) for low-rise / residential buildings | |||

| Opaque Elements | Zone 1 | Zone 2 | Zone 3 |

| Roofs | 0.31 | 0.37 | 0.42 |

| Walls | 0.53 | 0.61 | 0.7 |

| Opaque Doors – All Assemblies | 2.84 | 2.84 | 2.84 |

| Vertical Glazing, 25% of Wall | |||

| All Assemblies | 2.67 SHGC – 0.25 | 2.67 SHGC-0.25 | 2.67 SHGC – 0.25 |

| Skylight with Curb, Glass, % of Roof | |||

| 0% – 3% All Types | 4.26 SHGC – 0.35 | 4.26 SHGC – 0.35 | 4.26 SHGC – 0.35 |

Table 2 is applicable for Low-rise / Residential buildings (built by/for governmental entities), and need to be implemented starting from 25/11/2014 beyond January 1, 2017. It will be applicable for Low-rise / Residential buildings built for private or governmental entities.

| Table:2 – The thermal transmittance (U-Values) for low-rise / residential buildings | |||

| Opaque Elements | Zone 1 | Zone 2 | Zone 3 |

| Roofs | 0.20 | 0.24 | 0.27 |

| Walls | 0.34 | 0.4 | 0.45 |

| Opaque Doors – All Assemblies | 2.84 | 2.84 | 2.84 |

| Vertical Glazing, 25% of Wall | |||

| All Assemblies | 2.67 SHGC – 0.25 | 2.67 SHGC-0.25 | 2.67 SHGC – 0.25 |

| Skylight with Curb, Glass, % of Roof | |||

| 0% – 3% All Types | 4.26 SHGC – 0.35 | 4.26 SHGC – 0.35 | 4.26 SHGC – 0.35 |

Technical studies and research proved that the Rock Wool is one of the best insulation materials for reducing successfully the heat transfer through the insulated walls or roofs, and saves more than 50% from the consumption of the heating / cooling energy.

The following table shows the thermal comparison between the non-insulated and the insulated stone wall with Rock Wool.

| Construction Element | Impassivity | Thick mm | Thermal Resistance m2c’/w | |

| Before Insulation | After Insulation | |||

| External air film | High | – | 0.060 | 0.060 |

| Building stone | 70 | 0.050 | 0.050 | |

| Concrete | 200 | 0.114 | 0.114 | |

| RW Panels | 50 | – | 1.47 | |

| Hollow bricks | 100 | 0.111 | 0.111 | |

| Plaster | 20 | 0.0167 | 0.0167 | |

| Internal air film | – | 0.123 | 0.123 | |

| Total Thermal Resistance m2 K/W | 0.47 | 1.94 | ||

| Thermal Transmittance (U Value) w/m2 K | 2.10 | 0.51 | ||

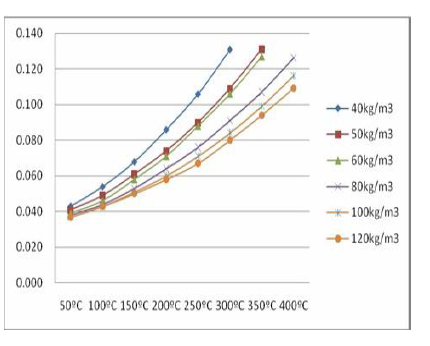

Rockwool has low thermal conductivity which is considered as an excellent building thermal insulation material. Its thermal conductivity is almost the same or better than most of the other petrochemical insulation materials, when measured at the actual operating temperature of 35 ºC which means temperature of the severe ambient hot condition (45-50 ºC) and the comfortable internal temperature (24-27 ºC).

Rockwool has low thermal conductivity which is considered as an excellent building thermal insulation material. Its thermal conductivity is almost the same or better than most of the other petrochemical insulation materials, when measured at the actual operating temperature of 35 ºC which means temperature of the severe ambient hot condition (45-50 ºC) and the comfortable internal temperature (24-27 ºC).

The thermal conductivity of ARW products are tested by SASO, King Saud University, and by R&D Laboratory with the products achieved low thermal conductivity.

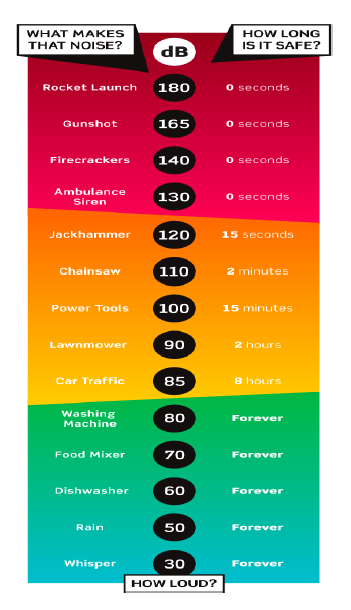

Sound is measured in decibels (dB). Human range of hearing starts at 0 dB and is considered safe up to 80 dB. Over and above that level is hazardous and can result in permanent hearing damage.

The Noise Reduction Coefficient (NRC):

Is a scalar representation of the amount of sound energy absorbed upon striking a particular surface. An NRC of 0 indicates complete reflection; an NRC of 1 indicates 0 reflection. NRC is the average absorption of material at four frequencies (250, 500, 1,000 and 2,000 Hz). The structure of the Al Tazi Rock Wool makes it an ideal product as sound absorbent due to its surface open cells structure. It will not reflect the sound waves striking its surface. Rockwool above 2” thickness will have almost 1 NRC. As a result, Al Tazi Rock Wool is very effective to control the reverberation time of the place securing comfortable living and listening. In this case, Rock Wool boards are normally covered with decorative porous fabric (cloth) and installed inside the rooms / halls, theaters, cinema, etc.

The Sound Transmission Class (STC) indicates the average sound transmission loss within the audible range of frequency for wall or partition, higher STC is better insulation. Installing Rock Wool through wall partition or cavity wall will reduce the sound transmitted between the adjacent rooms. Rockwool as a flexible porous damping material will dampens the mass-air-mass resonance provided with soft coupling between the two panels of partition and it reduces the reverberation in the cavity thus reducing the buildup of sound between the two sides of partition increasing the sound transmission class (STC) of walls / partitions. The minimum STC for partitions is specified by the related building codes as per the intended application of partition.

| Wall Type | STC |

| Between apartments of multi store building | 53 |

| Between classroom and sport hall (school) | 55 |

| Between classroom (school) | 47 |

| Between bedroom and corridors (Hotel) | 47 |

3- Fire Characteristics

Melting point: Due to its in-organic (mineral) composition, ARW Rock Wool has high melting point of 1,100 ˚C. Therefore, can safely operate at 750 ˚C without any degradation in thermal insulation performance.

Reaction to fire: Combustibility is a measure of how easily a substance will burn through fire.

Computability: is measured using the vertical furnace method according to EN 1182, samples are placed inside furnace at high temperature. The increase of furnace temperature, mass loss of samples, and duration of flaming are measured (it should be within certain limits).

Other related characteristics for fire classification of material is the heat of combustion (heating values) which indicates the amount of heat (calories) released by material when exposed to fire, tested according to EN 1716. In case the heating value is within certain limit, and material is noncombustible then the reaction to fire of material is A1.

The common building materials such as block and steel has A1 reaction to fire classification. Rock Wool is tested at Al Tazi Rockwool Laboratory and it achieved A1 classification which means it is noncombustible material and will not emit toxic fumes when exposed to fire.

Flame Spread Index and Smoke Developed Index

This test indicates how fast will flame propagate on surface of material and what will be the smoke density in case material is subjected to source of ignition from one portion. The values are compared to reference materials (cement board 0 values and wood 100 value). This property is tested according to ASTM E84, or UL 723. ARW Rock Wool products can be classified with zero flame spread index and zero smoke developed index, which means ARW Rock Wool insulation will not assist the spread of fire and will not emit fumes when exposed to fire.

4- Fire Resistance

Using Rockwool through partitions will improve the fire resistance of wall or roofs it will delay the fire to spread from place to another, and will give enough time before the fire spread. Fire resistance is measured according to ASTM E119, or EN 1363-1 for the complete construction system (wall, roof, or door including the components of the partition) where the system is exposed to hot temperature according the time temperature curve, and the cold surface temperature is measured. Rock Wool is recommended to be used in fire proofing systems. It is widely used as fire stopper in the expansion joints between the block work and concrete slabs. Rockwool slabs are coated with special fire coating materials with intumescing properties and used to fill the cavities between the flat ceiling and concrete slabs this will eliminate the spread of fire between the adjacent rooms. Rock Wool is widely applied in offshore oil drilling platform for person and equipment protection.

5- Water & Moisture Absorption

Water or moisture have negative effect on the thermal conductivity of the insulation materials and their insulation efficiency. ARW products are treated with water repellant emulsion oil, the insulation is water repellent non capillary and hydrophobic. Insulation doesn’t have the tendency to absorb water from the sever humid environment. The water vapor sorption of ARW products are continuously tested in Al Tazi Laboratory as part of Factory Product Control (FPC) according to ASTM C 1104 / 1104 M. Using humidity chamber and EN 1609 using water bath. ARW products are also tested by SASO, results are very satisfactory.

Corrosion Resistance

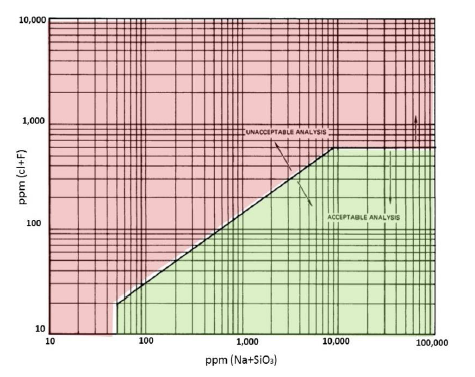

The presence of Leachable Chloride, and fluorides in the Rock Wool can cause corrosion to the insulated stainless steel surface especially in the presence of electrolyte (moisture from insulation or environment). The presence of sodium and silicate ions in the insulation has been found to inhibit external stress corrosion cracking. ARW fibers are treated to have minimum chloride and fluoride ions. The leach ions of ARW products is tested according to ASTM C871 and found within acceptable zone stated by figure 1 ASTM C795.

ARW products are tested by R&D Laboratory (USA) for corrosiveness to steel, copper, and aluminum according to ASTM C665 section 13.8, where metal plates covered with Rockwool are placed inside environmental chamber at severe humid conditions, steel sample is placed for 96 hours, the aluminum and copper samples are tested for 720 hours, all samples passed the test.

6- Non Aging Material

Rock Wool is mainly produced from Basalt rock which is chemically inert, Rock Wool cells structures contains static inactive gas (air), consequently, the Rock Wool will not be effected by aging factors, and can withstand severe conditions. Thus it is non aging material, the aging of Rockwool products is tested at Al Tazi Laboratory according to EN 1607 where the products are tested at accelerated environmental conditions, found within the acceptable range of EN 11362.

7- No Health Hazard

ARW products are tested by Al Hoty Stanger and approved to be Asbestos free. In general, Rockwool products are classified as noncarcinogenic to human according to the International Agency for Research on Cancer (IARC). Normally, the end user (occupant) will not be exposed to the insulation; hence, there is no possibility to cause any health hazard to them. However, it is always recommended to the contractor or installer to have suitable protection while installation, wearing long cloth, hand gloves, and dust masks. (material safety data sheet is available on website). ARW products are tested by R&D Laboratory (USA) for odor emission according to C-1304, the products are tested at high temperature, the odor is evaluated by committee of five expert person and approved that it will not emit unacceptable odor.

8- Environment Friendly

No harmful industrial wastes are produced from Al Tazi Rock Wool production processes, the solid wastes are efficiently recycled as per LEED requirements, the exhaust gases are treated and reduced to the international acceptable limits. The use of Rock Wool as a thermal insulation significantly reduce the environment pollution due to decrease of the energy consumption, reducing the emitted gases from power plants.

9- Vermin Proof

Rock Wool is unfavorable environmental media for the growth of fungi, bacteria, vermin, and pests. ARW products are tested by R&D Laboratory (USA) for Fungi Resistance by placing three Rock Wool samples through testing chamber for 28 days’ inoculation period at severe conditions according to ASTM C1338 standard. Every samples passed the test, and did not show any fungi growth.

10- Light Weight, Easy to Handle and Install

Rock Wool is relatively light weight compared to most of building materials, it will not cause significant load to the buildings. ARW products are easy to handle, fabricate to the required size using simple sharp edge knife or saw, for some applications. ARW products can be installed without any fixing fixtures such as drywall, cavity wall, roof hanger applications, where insulation is friction fit between the dry wall studs or between the two masonry walls, other applications require suitable fixing accessories such as adhesives, insulation fastener or insulation anchor, stuck up pin.